Niobium is a gray-white metal with a melting point of 2468 ° C, a boiling point of 4742 ° C, and a density of 8.57 grams per cubic centimeter. Niobium is stable in air at room temperature and does not oxidize completely at red heat in oxygen. It can be directly combined with sulfur, nitrogen and carbon to form alloys with titanium, zirconium, hafnium and tungsten at high temperature. It does not react with inorganic acids or bases, nor is it soluble in aqua regia, but soluble in hydrofluoric acid.

The use and application field of niobium

iron industry

About 85% to 90% of the world's niobium is used in steel production in the form of ferroniobium. Only adding 0.03% to 0.05% niobium to the steel can increase the yield strength of the steel by more than 30%. Niobium can also realize the dispersed distribution of precipitates by inducing precipitation and controlling the cooling rate, and adjust the toughness level of steel in a wide range. Therefore, adding niobium to steel can not only increase the strength of the steel, but also improve the toughness, high temperature oxidation resistance and corrosion resistance of the steel, reduce the brittle transition temperature of the steel, and make the steel have good welding performance and formability.

Superconducting material industry

Some compounds and alloys of niobium have a high superconducting transition temperature, so they are widely used in the manufacture of various industrial superconductors, such as superconducting generators, accelerator high-power magnets, superconducting magnetic energy storage devices, nuclear magnetic resonance imaging equipment, etc. . At present, the most important superconductor materials are niobium-titanium and niobium-tin, which are widely used in magnetic resonance imaging instruments for medical diagnosis and nuclear magnetic resonance instruments for spectral lines (analysis).

aerospace industry

The aerospace industry is the main application field of high-purity niobium, which is mainly used in the production of engines and heat-resistant parts of rockets and spacecraft. The heat-strength alloy of niobium and tantalum has good heat strength, heat resistance and processability, and is widely used in the manufacture of parts of aero-engines and blades of gas turbines.

atomic energy industry

Niobium has good thermal conductivity, high melting point, good corrosion resistance, and low neutron capture cross section, making it a very suitable material for atomic energy reactors. The main uses of niobium in the atomic energy industry include: cladding materials for nuclear fuel, alloys for nuclear fuel, and structural materials for heat exchangers in nuclear reactors.

electronics industry

Niobate ceramics can be used to make capacitors. Compound single crystals such as lithium niobate and potassium niobate are new crystals for optoelectronics and electronics. They have good piezoelectric, pyroelectric and optical properties and are widely used in infrared, laser technology and in the electronics industry. In addition, niobium has a high melting point, strong ability to emit electrons, and has the ability to get gas, so it can be used to make electron tubes and other electric vacuum devices.

medical field

Niobium has good physiological corrosion resistance and biocompatibility, will not interact with various liquid substances in the human body, and will hardly damage biological tissue, and can adapt to any sterilization method, so it is often used in Manufacture of bone plates, skull plate screws, dental implants, surgical instruments, etc.

other apps

In the chemical industry, niobium is a high-quality material resistant to acid and liquid metal corrosion, and can be used to make digesters, heaters, coolers, etc. In addition, niobic acid is also an important catalyst.

Niobium is also applied to the foundry industry. Its main function is to form hard carbides (good for wear resistance) and change the shape and size of graphite sheets. Therefore, it is often used to manufacture cylinder heads, piston rings and brake pads of automobiles, etc. . Niobium helps to increase the light transmission performance of the lens, so it is also used in the manufacture of lenses in the optical industry.

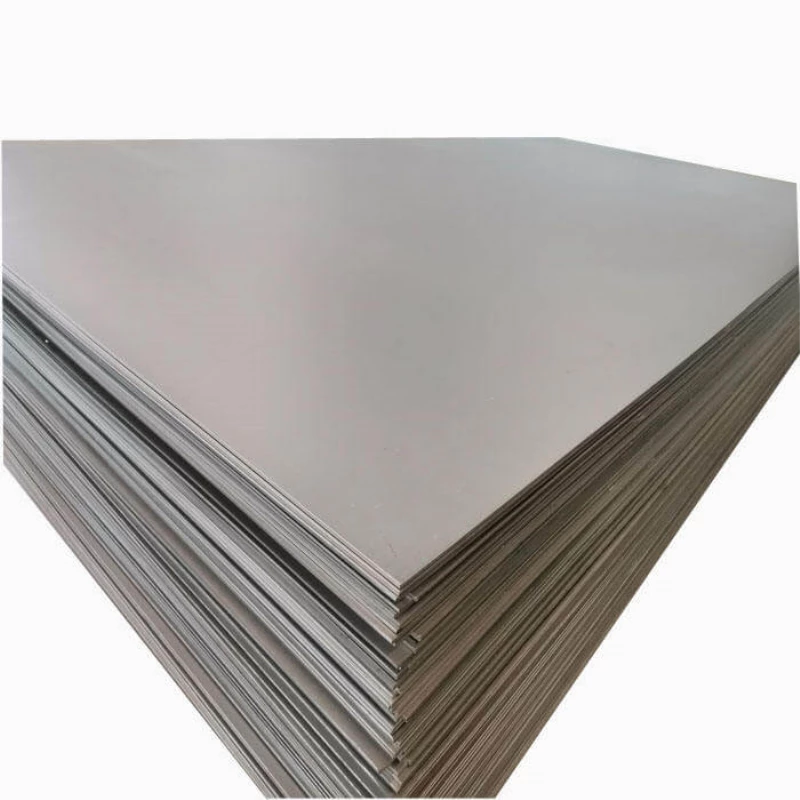

| Product Name | Pure Niobium Plate/Sheet |

| Material | Pure niobium and niobium alloy |

| Dimension | As per your request |

| Grade | RO4200.RO4210,R04251,R04261 |

| Process | Cold rolled, Hot rolled, Extruded |

| Characteristic | Melting point : 2468℃ Boiling point : 4744℃ |

| Application | Widely used in chemical, electronics, aviation and aerospace fields |

| Product Features | Excellent Corrosion Resistance Good resistance to effect of heat |

| Niobium and Niobium Alloys Sheet Chemical Composition | ||||

| Element | Type1 (Reactor Grade Unalloyed Nb) R04200 | Type2 (Commercial Grade Unalloyed Nb) R04210 | Type3 (Reactor Grade Nb-1%Zr) R04251 | Type4 (Commercial Grade Nb-1%Zr) R04261 |

| Max Weight % (Except Where Otherwise Specified) | ||||

| C | 0.01 | 0.01 | 0.01 | 0.01 |

| N | 0.01 | 0.01 | 0.01 | 0.01 |

| O | 0.015 | 0.025 | 0.015 | 0.025 |

| H | 0.0015 | 0.0015 | 0.0015 | 0.0015 |

| Zr | 0.02 | 0.02 | 0.8-1.2 | 0.8-1.2 |

| Ta | 0.1 | 0.3 | 0.1 | 0.5 |

| Fe | 0.005 | 0.01 | 0.005 | 0.01 |

| Si | 0.005 | 0.005 | 0.005 | 0.005 |

| W | 0.03 | 0.05 | 0.03 | 0.05 |

| Ni | 0.005 | 0.005 | 0.005 | 0.005 |

| Mo | 0.01 | 0.02 | 0.01 | 0.05 |

| Hf | 0.02 | 0.02 | 0.02 | 0.02 |

| Ti | 0.02 | 0.03 | 0.02 | 0.03 |

feature

1. Low density and high specification strength2. Excellent corrosion resistance

3. Good heat resistance effect

4. Unique characteristics such as high melting point, good corrosion resistance, and good superconductivity

application

1. Make jewelry;

2. Sodium vapor lamps;

3. Capacitors, smelting ingots and alloying agents.

4. Used in steel, ceramics, electronics;

5. Nuclear energy industry, superconducting technology

我们为您提供了更多类别。如果你在上面找不到你想要的产品,只需填写表格,告诉我们你想从中国进口什么产品。